A sprinkler system offers optimal fire protection in areas where there is little to no risk of rapid fire spread. Because the nozzles of a sprinkler system automatically open if the temperature increases beyond a designated threshold, sprinkler systems provide a quick response during any fire emergency. Sprinkler systems typically provide optimal coverage and protection in areas where personnel are usually present, like commercial buildings, offices, living quarters, workshops, and similar areas.

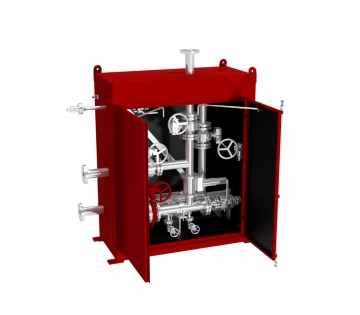

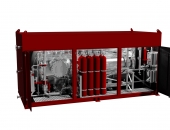

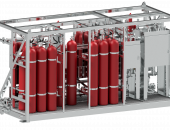

A sprinkler system connects closed nozzles to water supply through a network of pressurized pipework. In the standard Firenor design, a closed on-off valve controls the water supply, though a pressure regulating sprinkler valve is available when necessary. The system is fully equipped with all necessary valves and instrumentation for easy operation, maintenance, and testing. The release mechanism is automatically controlled via a pressure decrease in the pipe system whenever a sprinkler nozzle has been activated. A Firenor sprinkler system can be customized to meet any project requirements. For example, the sprinkler system can be adapted to cold locations where pipefreezing is a concern by filling the pipe network with air instead of water and by storing the system in an insulated cabinet instead of an open frame. All customized sprinkler systems are built precisely to customer requirements and full flow pre-tested to ensure quality before delivery.

Every system can be customized, upon request, for compliance with applicable rules, regulations and project specific requirements as well as standard such as CE, FM, UL, ASME, DIN, DNV, BV, NMD, IMO, NFPA, Norsok. Full documentation for any tailor-made products are available and include all necessary certifications, third party verifications such as DNV/GL, BV, ABS, etc., and full scale test reports, if required.

Firenor can deliver variety of sprinkler nozzles with different flow and release temperatures for use with the sprinkler skid.

A sprinkler nozzle uses a simple and well known activation method. A glass bulb is sealing the nozzle. The glass bulb is filled with alcohol and a small air bubble. When the temperature reaches a certain designated point, the expanding air bubble causes the bulb to burst. Water released from the nozzle strikes the deflector and creates a spray in the designated area.

In addition to providing sprinkler nozzles, Firenor offers its years of industry experience to properly place the nozzles and perform all hydraulic calculations, for maximum efficiency of fire protection.

- Outlets from 2- 12 inches

- Regulating or non-regulating deluge Valve

- Flexible design

- Compatible with various hazardous area classifications and regulations (ATEX, UL, CSA etc.)

- Full-scale tests up to 35 000 LPM

- Working environment friendly design

Every Firenor system is available in the following materials:

- Galvanized carbon steel

- Copper nickel

- Super duplex

- Titanium

- Duplex

- SS316

- 6Mo

- GRE

The engineering department produces documentation relevant to all phases of the project. Documentation normally includes the following:

- Quality plan

- ITP

- Drawings

- Data sheets

- Indexes

- Procedures

- Calculations

- Certificates

- Reports

- User manual

- MRB