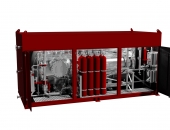

Foam role is to preventing burning liquid to contact with oxygen and resulting in suppression of the combustion. The Firenor foam system is connected to the foam ring main which efficiently supplies foam to all foam consuming equipment at the installation in the same way that firewater is supplied from the firewater pumps.

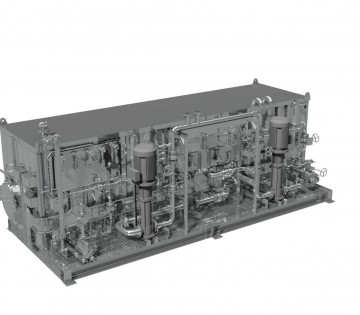

The Firenor foam system uses a redundant foam pumps to feed pressurized foam liquid from a foam tank reservoir to a distribution system. The foam pumps could be the centrifugal pump type or a positive displacement pump. The distribution system efficiently supplies foam to all foam consumers on site, like deluge skids, monitor skids, hydrants, hose reels, etc.

This system can be delivered with all standard options or customized to meet specific project requirements or a specific safety integrity level. Whether custom or standard, the system is always equipped with all required valves and instrumentation to allow for easy operation, maintenance, and testing. All systems are full flow pre-tested before delivery to ensure the quality of the equipment. The system can be utilized with air driven or electrical jockey pumps to keep up the required pressure in the foam ring main. The system can be utilized with test line as well therefore the performance of the system can be verified during test intervals.

Every system can be customized, upon request, for compliance with applicable rules, regulations and project specific requirements as well as standard such as CE, FM, UL, ASME, DIN, DNV, BV, NMD, IMO, NFPA, Norsok. Full documentation for any tailor-made products are available and include all necessary certifications, third party verifications such as DNV/GL, BV, ABS, etc., and full scale test reports, if required.

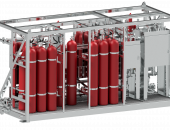

Firenor offers a wide variety of foam liquid types which can be set to any required percentage mix.

Both centrifugal pumps and positive displacement pumps are available. Firenor always includes the pump for a Foam System that is optimal for the type of foam being used.

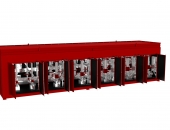

The centralized system can be designed with high rehabilitee compared to 1x100% local mechanical systems. This allows foam to be stored in a better environmentally controlled condition than if stored locally on each foam consuming equipment.

- Flexible Design

- Compatible with various hazardous area classification and regulations (ATEX, UL, CSA etc)

- Compatible with IEC 61508 for Safety Integrity Level 2

- Working environment friendly design

Every Firenor system is available in the following materials:

- Super duplex

- Duplex

- SS316

- 6Mo

- GRE

The engineering department produces documentation relevant to all phases of the project. Documentation normally includes the following:

- Quality plan

- ITP

- Drawings

- Data sheets

- Indexes

- Procedures

- Calculations

- Certificates

- Reports

- User manual

- MRB